Hope you’re sitting comfortably as I’m about to tell the whole tale of my trip to IVA. It started about 6 weeks ago when I finally plucked up the courage to send the forms off, I wasn’t quite ready but there’s nothing like a deadline to focus the mind. Unfortunately I failed at the first hurdle, misread the guidance notes and sent off a cheque for the wrong amount. I baulked a little at the £195 but when I found out it should be £450 I nearly fell off my chair. It took about a week for VOSA to tell me I’d sent the wrong amount and then about another week for them to process my application after I’d paid the extra and then another week for the IVA test centre to receive the paperwork. I then had a three week wait for an appointment.

I’d always planned to go for a pre-IVA MOT in order to have a shake down before the big test, give me a chance to bed the brakes in and have someone with a little more knowledge than myself give the car a once over. Given the wait I now had I was even more keen as it was also a good excuse for a drive, this has been just under 5 years in the making and I was itching to get it on the road.

My wife came with me in the “support car” and the MOT went fine, it got a clean bill of health and the sun shone all the way there and all the way back. When you approach the village I live in, there is the short way to my house down a tight sharp turn or the long way, a bit further round the far end and back through the village itself. Given the circumstances, it had to be the long way despite flashing of lights and gesticulating hand gestures from my wife behind as she was supposed to be somewhere else and I’d already taken a little longer than I’d expected !

As I pulled into the far end of the village, the car began to behave a little strange, it was running very rough and it got gradually worse and worse until just before the hill up to where I live it died and I coasted to a standstill just outside the local chip shop. Expecting it to be lack of fuel, the “not very impressed” wife was despatched off to the local garage with a can as I sat a little embarrassed, outside the chip shop as people slowed down to look and stare. One guy was so intent he slammed on the brakes and backed up without even looking behind. This resulted in the angry sound of a horn and waving fist of the guy behind as he had to violently swerve to avoid an accident.

The wife arrived back with the fuel which was duly poured into the filler for a frantic last blast up the hill to home so she could get off to her other appointment BUT... the car wouldn’t even turn over and I was greeted by the click click click of the starter solenoid. By now a crowd had started to gather including an older gentleman who asked if I would mind if he took some photographs as “you don’t often see old cars like this still on the road”. I just smiled and nodded my head. A quick poll of the onlookers determined no one had jump leads or a tow rope so I jumped in the “support vehicle” and headed for a neighbours who I was sure would have a tow rope, he did and I returned to unceremoniously tie the rope onto the cobra and tow it home with the wife behind the wheel. At least she got to drive it eh ?.

Further investigation showed the cause to be a dodgy alternator and with now only two weeks before the test I had to get a replacement. Andy at GD helped me with this and within a couple of days everything was back to how it should be. The next week was spent tidying a few loose ends and getting everything ready for the IVA.

Two days before the IVA test, one of the last jobs was to wash and polish the car and put the labels on the dash to identify the various controls. Whilst doing this I ran through a few last minute checks when everything started to take a turn for the worse.

The first thing I noticed was a strange clicking noise when turning the key in the ignition, sometimes it did it and sometimes not. Whilst trying to narrow it down, checking relays etc I also tried some of the controls such a windscreen wipers, lights, indicators etc. Whilst I was around the front of the car checking the headlights, smoke started pouring out from the dash, fearing the worst my first reaction was to run into the garage to find a 17mm spanner to undo the battery leads form the studs under the bonnet. With the reduced access in this area coupled with the fear of shorting the live and neutral terminals with the spanner, it seemed like an age before it was finally disconnected, all the while with smoke pouring out from the dash, my kids staring at Daddy wondering what was happening and my wife panicking in my peripheral vision.

I really thought I was going to lose it and it would go up in flames. It didn’t and what followed next was quite an emotional period which needs no further explanation !

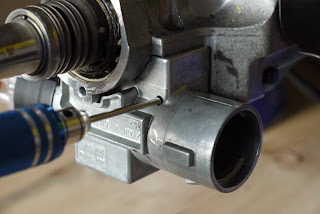

Once I had recomposed myself and had the presence to return and examine the damage it was apparent some kind of short had occurred behind the dash and several wires had burnt their plastic covering off over their whole length and melted and fused other circuits together, burning straight through the leather trim and piping which also ran in this area. It was a real mess and with the burnt wiring, plastic zipties and leather piping it smelt terrible as well. In order to gain proper access I had to remove the steering column, dash under trays and finally the dash itself all the while wondering what I would discover. Using the circuit diagram it appeared the most likely fault lay with the wiper motor and sure enough, testing it with a multimeter showed a direct short to earth. Ordinarily you would have expected a fuse to blow but for some reason it didn’t and by the time the various circuits had fused together it was too late anyway.

With two days to go until the IVA test I couldn’t re-arrange without forfeiting the whole fee. With the prospect of losing £450 I made the decision, come hell or high water I would attempt to fix the problem and turn up for the test even if it had to be towed there. At least if it couldn’t be tested properly I only faced the prospect of a retest at £90 and I might be in for a retest anyway as I was told only very few builds pass first time.

Again, a call to Andy at GD got me a replacement loom and wiper motor and with now only one clear day before the test I had to pull a late one until 1am in the morning to get everything back together before a very tentative recheck of all the electrical circuits, 17mm spanner in hand a fire extinguisher standing by. I’m very pleased to say it all worked fine, didn’t melt itself into a mass of fused plastic and copper wiring and didn’t burst into flames.

The next day was work as usual and the evening spent carrying out all the smaller jobs I’d intended to do two days before, labelling the dash, checking wheel nuts were tight as well as packing most of my tools, rubber edging and zip ties etc in order to be as well prepared as possible for anything the IVA test might throw up. I’d heard that generally, the examiners want you to pass and if there was an opportunity to fix anything on the day, there might be a certain amount of leeway.

I had an early start the next morning and had to be away from home around 7 for the drive to the test centre to be there for 8am. One last job before bed was to print off a selection of photographs to take with me, partly to provide some kind of proof that I’d actually built it but also to show the examiner details of any areas which now might be covered such as wiring which was now hidden by carpet or brake lines hidden behind footwell compartments etc. First problem, the printer had run out of paper, finding an old report from work, noting sensitive, I turned it over to print on the back. Time and time again I tried but on each occasion, the paper jammed and I had to pull the crumpled paper out and start again. On the 4th or maybe 5th time I spotted a strange red foreign object inside the printer which turned out to be part of one of my kids toys and was the reason the paper kept jamming. Carefully pulling it out and for the second night staying up past midnight I was now on the home straight, that was until the printer ink ran out! In despair, I copied the photos onto a CD ROM and added a laptop computer to my tool kit to display them on. Finally, I got myself off to bed, completely exhausted, physically, mentally and emotionally. I had done all that was possible, if I failed now it wouldn’t be through lack of effort.